Some years ago I was the project manager – on the client side – of the renovation of the Vondelpark pavilion in Amsterdam, a 130-year-old building and state monument of about 2,500 sqm in the Amsterdam Vondelpark. The challenge was to change the building from an old building into a modern venue for radio, television, and internet broadcasting, including a modern restaurant with all its facilities and two recording studios for an audience of about 60 persons each.

One of the challenges was to braid all the needed modern technical equipment into the building and add the needed acoustic measures, logistics, and fire safety. Imagine that in the old days, technical installations were hardly part of a building. Water, sewage, a boiler for heating and electricity. Nowadays we incorporate cooling, mechanical ventilation, data, wifi and we use much more electrical stuff. When it comes to broadcasting a huge amount of extra technical equipment is needed and this all needs electricity, cooling, and ventilation. We had to incorporate special acoustic measurements into the design.

The fact that the building is a state monument made the design an even bigger challenge. Close collaboration between the architect and several technical engineers was needed to finish the building specifications.

You can imagine that also the construction process came with the same kind of challenges as the design. But design is on paper and building is for real.

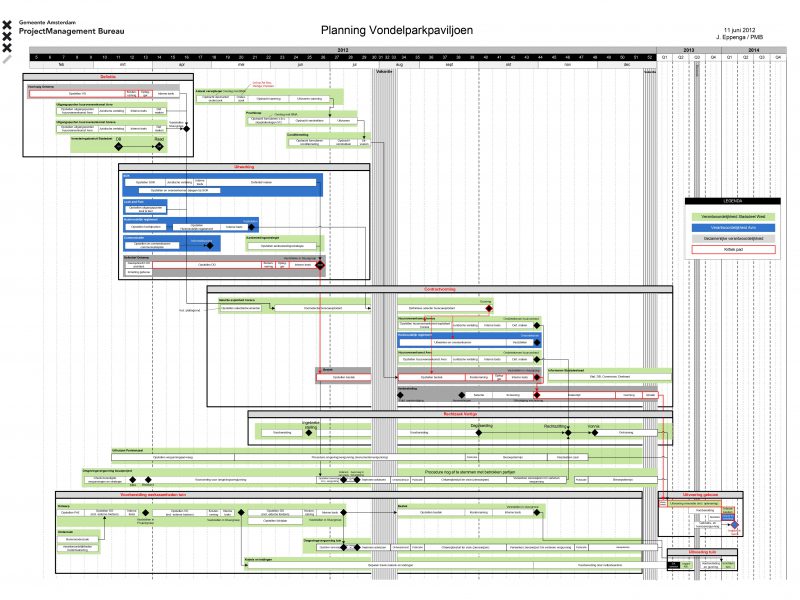

One management tool a contractor uses to steer a building process is the schedule. A schedule that is often enormously detailed. This is needed to plan ahead, instruct partners, be on time every day and detect anything that goes wrong or delays.

The contractor of the Vondelpark pavilion used a lean planning and management method to design the construction process. They did a great job!

How did it work?

The lean schedule was made together with the main subcontractors. the carpenters, the masons, steel workers, electricians, plasterers, ventilation guys, painters. All partners planned their daily work for the coming months and discussed the relations and the interface of their works. This process took several days and the result was an enormous schedule covering all the walls of one of the rooms in the building.

This schedule was reviewed by the site manager and experts and later approved by all workers.

At the start of each working day, the team came together to discuss the main day tasks and goals. This took only a quarter or half an hour and the result was that everyone on site understood mutual goals and interdependencies.

The result.

- Fewer clashes between workers of different traits.

- Fewer ad hoc stuff for the site manager to solve. Workers solved their problems together.

- A better understanding of the work of others.

- A growing team spirit

Of course, we still had several issues and setbacks during construction, we discovered faults in the building specifications and had to deal with the additional wishes of the clients. It turned out that the contractor was able to adapt his lean planning to these disruptions.

It was the first time my contractor worked with lean planning on site and my experience is positive!

2 comments

I’ve been to the pavilion a few times this summer. It is a really nice place to go for a drink. That said..

How did the parties of the project looked at the ‘new’ method of planning. Were there any parties who said “Well, post-its? We don’t want that!”

Hi Alptug, I did not hear of any party who refused to work together in the LEAN way. And I think that is good and understandable. It was maybe stated in their contracts.